Both Traditional Heavy Duty (HD) hand sewn tarps and Radio Frequency (RF) welding are methods of manufacturing tarps for commercial load containment, and each method comes with its own set of benefits.

Traditional Heavy Duty (HD) Hand Sewn Tarp

Traditional Heavy Duty (HD) Hand Sewn Tarp

Process: In hand sewing, skilled workers stitch the fabric panels of the tarp together using heavy-duty thread. This method involves manual labor and craftsmanship.

Benefits

-

-

- Durability: Hand-sewn tarps are known for their strength and durability. The stitching creates a robust bond between panels, making the tarp resistant to wear and tear.

- Customization: Hand sewing allows for greater customization. Skilled artisans can create tailored solutions, making it possible to produce tarps of various sizes and specifications.

-

RF Welding (Radio Frequency Welding)

RF Welding (Radio Frequency Welding)

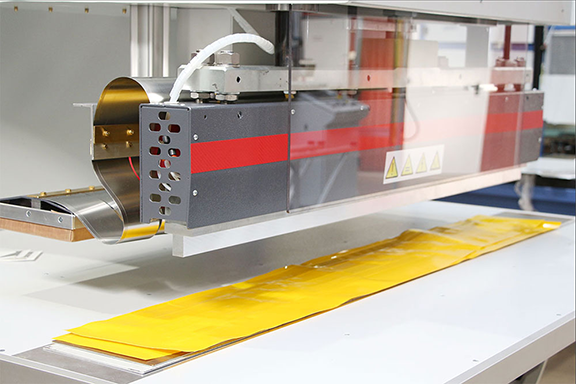

Process: RF welding, also known as high-frequency welding, uses electromagnetic energy to heat and fuse the seams of the tarp. This process is automated and relies on specialized equipment.

Benefits

-

-

- Seam Strength: RF welding creates a seamless bond along the edges, ensuring a strong and waterproof seal. This method is particularly effective in preventing leaks and enhancing the overall integrity of the tarp.

- Efficiency: RF welding is a faster and more automated process compared to hand sewing. This can result in increased production efficiency, making it a preferred choice for mass production.

-

Choosing between Traditional HD Tarps & RF Welded Tarps

- Application: Consider the intended use of the truck tarp. For heavy-duty applications where durability is crucial, Traditional HD tarps may be preferred. On the other hand, RF-welded tarps might be suitable for applications where efficiency and precision are key.

- Budget and Volume: Traditional HD tarps involves skilled labor, which increases quality and durability but also cost. If cost is a significant factor, RF welding may be a more cost-effective but still reliable solution.

- Customization Needs: If your truck tarp needs to be highly customized in terms of size, shape, or features, hand sewing may be the better option, as it allows for more intricate designs and tailored solutions.

- Material Considerations : The material used for tarp construction is contingent upon the application, for instance an Ag tarp used for transporting grain or other moisture sensitive cargo would require a moisture resistant material like vinyl, while aggregate can be hauled using mesh or canvas. Learn more about tarp material selection for both Traditional HD and RF Welded tarps.

The choice between Traditional HD and RF Welded Tarps depends on factors such as the intended use, budget constraints, volume of production, and customization requirements. Both methods have their advantages, and the decision should align with the specific needs and priorities of the truck tarp application.

Our Customer Service team can help answer any questions you have to provide a durable tarp solution that will keep you on the road, contact them today with any questions!